Application mode and selection method of steel shield

The steel shield can be used to protect the screw rod, light bar, column, mandrel and other circular rotating columns. Can be used horizontally or vertically. It is recommended to use plastic or aluminum support ring when the level is used, to keep a certain distance between the inner cavity of the shield and the screw rod, and to extend the service life. When the length of the drawing is large, the metal ring can be added to each compromise to improve the stability of the shield. Metal flanges are usually used for connecting or fixing ends, and sleeve type can be also selected.

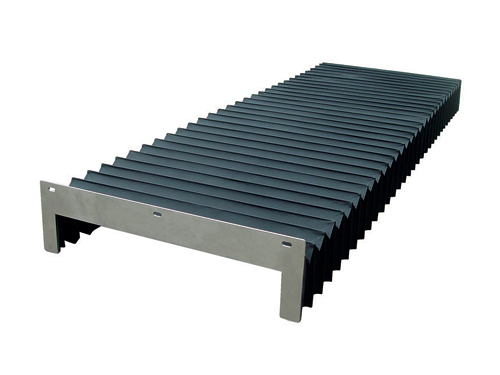

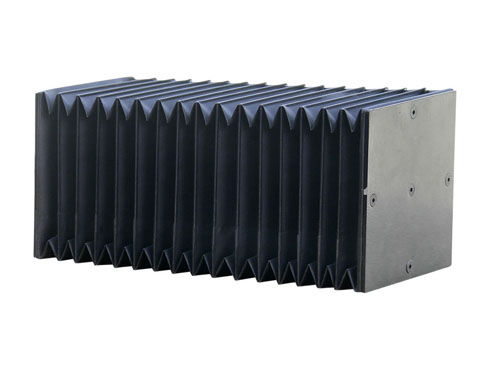

The steel plate shield is the traditional protection form of machine tool. In the field of steel telescopic guideway cover a wide range of applications, to prevent the entry of chips and other sharp things play an effective role in the protection, the structure of certain measures and appropriate scraping plate can effectively reduce the cooling liquid infiltration. Our steel telescopic rail shield can adapt to the modern machine tool for high technology, the correct installation position, high speed and other aspects of the continuous improvement requirements.

The steel shield is made of high quality 2-3mm thick steel plate by cold pressing, and can be made of stainless steel according to the requirement. A special surface finish will make it appreciate another. We can provide the type of rail protection for all kinds of machine tools (horizontal, vertical, inclined, transverse). According to the running speed and the guide rail, the shield structure is different. Under running speed 10m/min, we are equipped with poly grease or brass slider. Under medium speed 30m/min, we have rollers. A buffer system is also needed between the drive plate, the shaving pad and the shavings board. The aim of the slide buffer system is to reduce the impact, noise and friction.

The pitch number of the steel telescopic guide rail is very important to its proportion, weight and operation characteristics. Each single section should be as long as possible, which can reduce the number of nodes and reduce costs. In general, the ratio of tension and compression should be between 3:1 and 5:1.