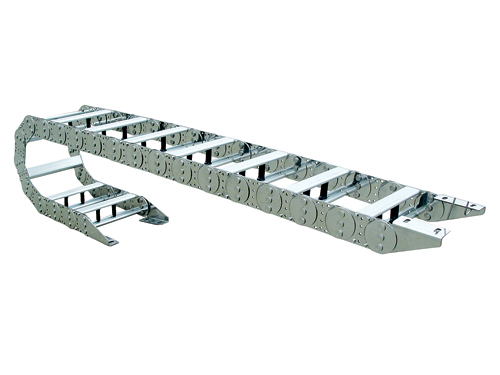

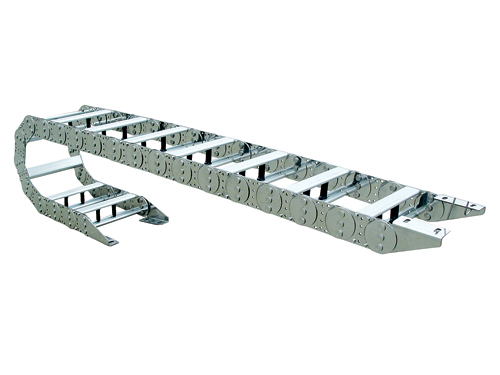

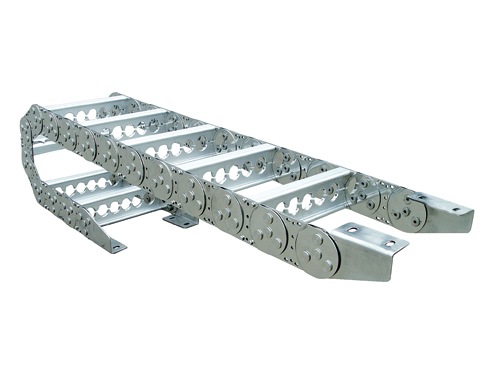

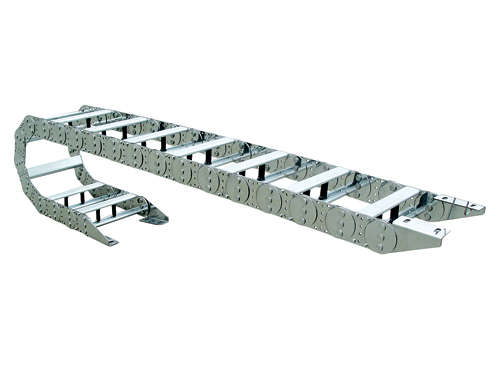

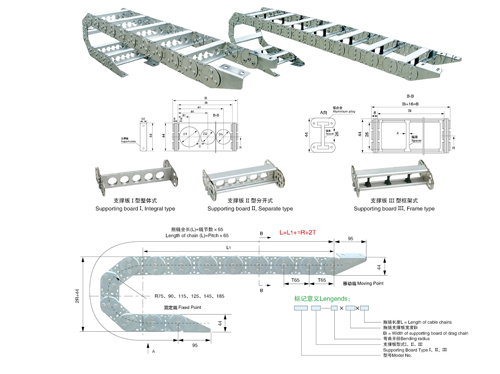

TL Series Steel Cable Chains

TL series steel cable drag chains

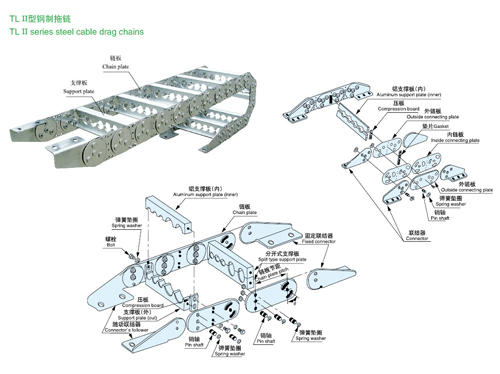

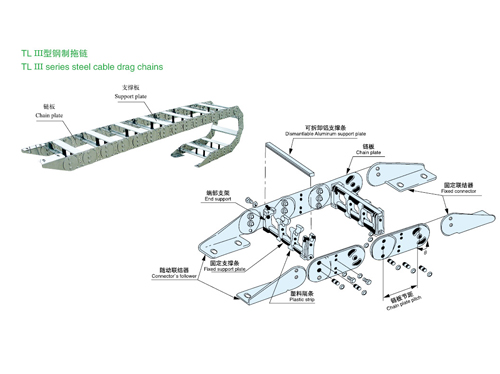

TL series steel cable drag chains are mainly consisting of chain plate (top quality stainless steel with chromium plated), supporing board (extruded aluminium alloy) and pinshaft (alloy),etc. there is no relative motions between the cable /rubber hoses and the drag giving no deforming or twists. The chromium plated chain board has very nice-looking appearance and has very rational construction and flecxible and high strength. It is reliable and easy to perate, install, dismantal or assemble .it is worthwhile mentioning that the anti-wearing performance has been improved greatly due to wear resistant material and alloy pinshaft are used .the product is flexible to bending and has low resistance .giving low noises. it can be used for a very long period of time without any deformation or hanging down.

the product is nice-looking, which makes the machine tool unit nicer looking as a whole and makes the machine tools and machineries more competitive in the international market

1.the drag chain can adapt to max. moving speed of 40m/sec.

2.when at the max moving speed. the sound pressure of noises shall not be greater than 68db.

3.the service life of the drag chain shall not be less than 1million times (reciprocating).

TL Series Steel Cable ChainsSpecifications

| Type | TL65 | TL80 | TL95 | TL115 | TL125 | TL155 | TL180 | TL225 | TL250 | TL325 | TL350 |

| Pitch | 65 | 80 | 95 | 115 | 125 | 155 | 180 | 225 | 250 | 325 | 350 |

| Bending radius | 75-185 | 100-300 | 115-300 | 150-300 | 200-750 | 200-750 | 250-650 | 350-1000 | 400-1000 | 350-1000 | 400-1000 |

| Minimum width of drag chain | 75-350 | 70-400 | 120-450 | 120-500 | 120-550 | 130-600 | 140-700 | 150-1200 | 500-1200 | 300-3500 | 350-2000 |

| Height ofdrag chain | 44 | 60 | 70 | 86 | 99 | 120 | 144 | 200 | 220 | 250 | 300 |

| Max.hole diameter of support plate | 30 | 35 | 40 | 60 | 70 | 80 | 90 | 120 | 140 | 200 | 350 |

| When non-support wheel isallowed | 6 | 7 | 9 | 10 | 10 | 10 | 10 | 10 | 10 | 12 | 12 |